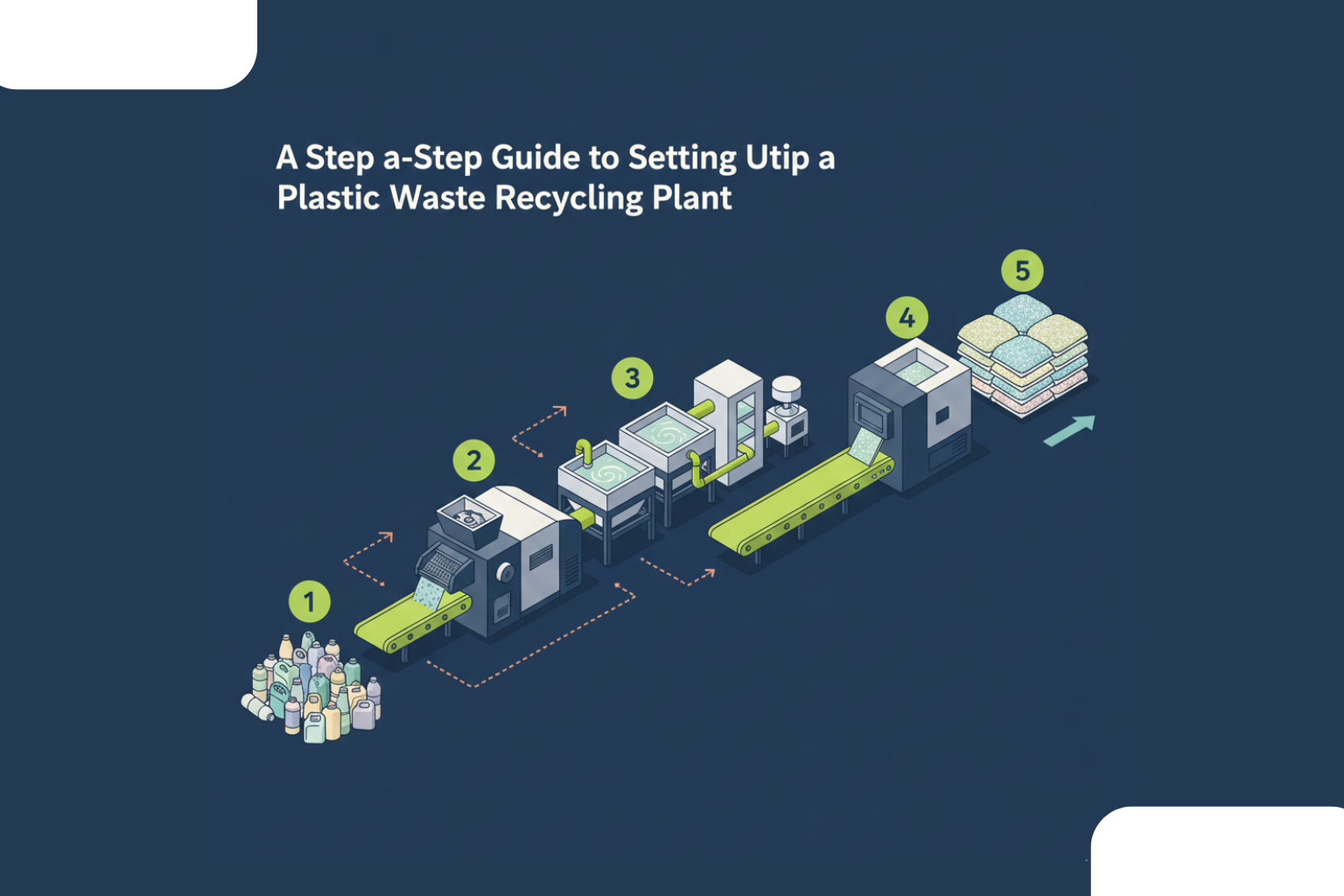

A Step-by-Step Guide to Setting Up a Plastic Waste Recycling Plant

Plastic waste has become one of the biggest environmental challenges in today’s world. Every year, millions of tons of plastic end up in landfills, rivers, and oceans. Setting up a plastic waste recycling plant is an effective way to reduce pollution while creating a sustainable and profitable business.

This blog explains, in simple and easy language, how a plastic recycling plant is set up and how the entire process works.

Why Plastic Recycling Is Important

Plastic recycling helps both the environment and the economy.

Key benefits include:

- Reduces plastic pollution

- Saves natural resources

- Lowers energy consumption

- Creates employment opportunities

- Converts waste into valuable raw material

Due to increasing government regulations and demand for recycled plastic, recycling plants are becoming more important than ever.

Step 1: Identify the Type of Plastic Waste

The first step in setting up a recycling plant is understanding the type of plastic waste to be processed, such as:

- PET bottles

- HDPE and LDPE plastics

- PP plastic waste

- Mixed plastic waste

Each type of plastic requires a different recycling method and machinery setup.

Step 2: Capacity Planning and Feasibility Study

Before starting the plant, it is important to decide:

- Daily processing capacity

- Space availability

- Power and water requirements

- Expected output quality

Proper planning helps avoid operational problems and unnecessary costs.

Step 3: Recycling Plant Layout Design

A well-planned layout ensures smooth workflow and efficient operations. The layout usually includes:

- Waste feeding area

- Shredding section

- Washing and cleaning units

- Drying system

- Material separation and storage area

An optimized layout improves productivity and reduces downtime.

Step 4: Machinery Used in a Plastic Recycling Plant

A plastic recycling plant typically uses:

- Plastic shredders to reduce size

- Conveyors for material movement

- Washing systems to clean waste

- Dryers to remove moisture

- Separation systems to sort materials

Using the right machinery ensures high-quality recycled output.

Step 5: Installation and Commissioning

After machinery installation, the plant undergoes trial runs to check:

- Machine performance

- Material flow

- Output quality

- Safety measures

This step ensures smooth and trouble-free plant operation.

Step 6: Operation and Maintenance

Regular maintenance and proper operation are essential for long-term success. A well-maintained plant:

- Operates efficiently

- Consumes less energy

- Produces consistent output

- Reduces breakdowns

Trained operators and routine checks help extend machine life.

Benefits of Setting Up a Plastic Recycling Plant

- Environment-friendly business

- Continuous demand for recycled plastic

- Scalable for future expansion

- Long-term profitability

- Supports sustainable development

Conclusion

Setting up a plastic waste recycling plant is a smart step toward solving environmental problems while building a sustainable business. With proper planning, the right machinery, and efficient operations, plastic recycling can deliver both environmental and economic benefits.

As industries and governments continue to focus on waste management, plastic recycling plants will play a key role in shaping a cleaner and greener future.